How to Choose the Right PU Machine for Your Manufacturing Needs: A Comprehensive Buyer's Guide

The global polyurethane (PU) equipment market is evolving rapidly, driven by demand for automation, energy efficiency, and customized production. Selecting the right PU machine is a critical decision that impacts product quality, operational costs, and business scalability. This guide, presented by industry leader Yongjia Polyurethane, provides a step-by-step framework to help manufacturers, from furniture to appliance sectors, make an informed investment.

Yongjia Polyurethane's advanced PU Foam Machine ensures precise mixing and high-efficiency output for diverse applications.

Step 1: Define Your Application and Product Type

Your primary product dictates the type of PU machine required. The market offers specialized equipment for various outputs:

- For Furniture & Seating: Consider a dedicated pu sofa machine, pu chair machine, or pu seat machine. These are optimized for molding complex cushion shapes with consistent density and comfort.

- For Home Appliances: Insulation is key. A pu machine for refrigerator (also known as pu fridge machine, pu freezer machine, or pu cooler machine) is engineered to inject foam into cabinet cavities with precision, ensuring optimal thermal efficiency.

- For Packaging & Bedding: A pu pillow machine is ideal for producing soft, molded foam inserts for packaging or comfort pillows.

- For Construction & Insulation: A versatile PU Spray Foam Machine is used for applying foam directly on walls, roofs, and tanks for insulation and sealing.

- For General Foam Production: A standard pu foam machine (High Pressure or Low Pressure) serves as a flexible core for various molding and casting jobs.

Pro Tip from Yongjia: Many manufacturers, like Yongjia Polyurethane, offer customized solutions. Discuss your specific product dimensions, output rate, and foam formulation needs with their engineers.

Step 2: Evaluate Key Machine Specifications and Technology

Beyond application, technical specs determine long-term performance and ROI.

| Specification | What to Look For | Why It Matters |

|---|---|---|

| Mixing Technology | High-Pressure Impingement Mixing vs. Low-Pressure Mechanical Mixing | High-pressure (like our High Pressure PU Foam Machine) offers superior mix quality, less waste, and is better for fast-reaction foams. Low-pressure is cost-effective for simpler applications. |

| Output Capacity & Shot Control | Precise metering pumps and programmable shot volume. | Ensures consistent product weight and density, critical for quality control in pu seat machine or pu machine for refrigerator production. |

| Automation Level | PLC control, robotic arm integration, data logging. | Reduces labor, improves repeatability, and enables Industry 4.0 integration for smart factories. |

| Energy Efficiency | Servo-driven systems, efficient thermal management. | Lowers operational costs and environmental footprint, a growing concern globally. |

Step 3: Assess Manufacturer Credentials and Support

The manufacturer's reputation is as important as the machine itself. Yongjia Polyurethane, a high-tech enterprise founded in 2013, exemplifies the credentials to seek:

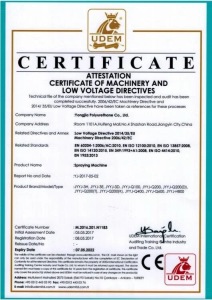

✅ Certifications & Compliance

Always verify international certifications. Yongjia Polyurethane equipment carries the CE Mark, guaranteeing compliance with EU health, safety, and environmental standards. This is non-negotiable for exporting products or ensuring workplace safety.

✅ Global Experience & Customization

A supplier with a global footprint understands diverse market needs. With exports to over 60 countries, Yongjia provides customized solutions, whether you need a specialized pu pillow machine or a complete PU Spray Foam Machine production line.

✅ After-Sales & Technical Support

Look for 24/7 support. Yongjia offers comprehensive services: installation guidance, operator training, remote troubleshooting, and readily available spare parts. This minimizes downtime—a crucial factor for continuous production with your pu foam machine.

Step 4: Consider Total Cost of Ownership (TCO)

Look beyond the initial price tag. The TCO includes:

- Energy Consumption: Efficient machines like Yongjia's reduce long-term utility bills.

- Maintenance & Spare Parts: Choose a manufacturer with a reliable supply chain and clear maintenance protocols.

- Raw Material Efficiency: High-precision machines minimize foam waste, saving material costs.

- Productivity Gains: An automated pu sofa machine increases output and consistency, boosting revenue.

Investing in a robust PU machine from a reputable supplier like Yongjia Polyurethane often yields a better TCO than opting for a cheaper, less reliable alternative.

Ready to Transform Your Production Line?

Connect with the PU machine experts at Yongjia Polyurethane for a personalized consultation. We provide everything from single machines like a pu seat machine or pu machine for refrigerator to complete turnkey solutions.

📞 Phone/WhatsApp: +86 13656166310

📧 Email: info@pufoammachine.com

🌐 Website: www.pufoammachine.com

🏢 Address: Room 1101, No.4 Shashan Road, Jiangyin City, Jiangsu Province, China

Disclaimer: This buyer's guide is for informational purposes. Machine selection should be based on a detailed technical evaluation of your specific requirements. All product names, logos, and brands are property of their respective owners.