How to Choose the Right PU Machine for Your Manufacturing Needs: A Comprehensive Guide

Selecting the ideal PU machine is a critical decision that impacts production efficiency, product quality, and overall business profitability. Whether you're producing furniture, appliances, or specialized foam products, understanding the key factors in choosing a polyurethane foam machine is essential. This How-To guide, presented by industry leader Yongjia Polyurethane, will walk you through the essential steps and considerations to make an informed investment.

Step 1: Define Your Application and Product Type

The first step is to clearly identify what you will be manufacturing. Different PU machines are optimized for specific outputs. Here’s a quick reference:

- For Furniture & Seating: Consider a dedicated pu sofa machine, pu chair machine, or pu seat machine. These are designed for consistent molding of cushions and backrests with specific density and comfort requirements.

- For Bedding & Accessories: A pu pillow machine is engineered for high-volume production of pillows, mattress toppers, and other soft furnishings.

- For Appliance Insulation: The refrigeration industry requires precise equipment like a pu machine for refrigerator, also known as a pu fridge machine or pu freezer machine. These machines ensure perfect foam filling for optimal thermal efficiency in pu cooler machine applications.

- For General Foam Production & Spraying: A versatile high pressure PU foam machine or a PU Spray Foam Machine is suitable for insulation panels, packaging, and on-site spraying applications.

As a full-solution provider, Yongjia Polyurethane offers this entire range, ensuring you get a machine perfectly matched to your product line.

A specialized pu machine for refrigerator from Yongjia Polyurethane, ensuring precise insulation foam filling.

Step 2: Understand Machine Technology: High Pressure vs. Low Pressure

Two primary technologies dominate the pu foam machine market:

| Feature | High Pressure PU Foam Machine | Low Pressure PU Foam Machine |

|---|---|---|

| Mixing Principle | Impingement mixing under high pressure for a thorough, homogeneous mix. | Mechanical stirring at lower pressure. |

| Output Quality | Superior foam cell structure, consistent density, excellent physical properties. | Adequate for less critical applications; may have more voids. |

| Material Waste | Very low, due to precise shot control and self-cleaning mixing head. | Higher, requires solvent flushing. |

| Ideal For | High-quality furniture (pu sofa machine), appliance insulation (pu fridge machine), automotive parts. | Simple shapes, packaging foam, lower-volume production. |

Yongjia Polyurethane recommends High Pressure PU Foam Machines for most industrial applications due to their efficiency, precision, and superior end-product quality, which aligns with global standards.

Step 3: Evaluate Manufacturer Credentials and Support

Your PU machine is a long-term investment. Partnering with a reputable manufacturer is crucial. Here’s what to look for, exemplified by Yongjia Polyurethane:

- Technical Expertise & Innovation: Founded in 2013, Yongjia is a high-tech enterprise focused on R&D. Their continuous innovation ensures equipment like their PU Spray Foam Machine and pu pillow machine incorporate the latest advancements.

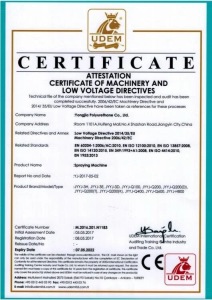

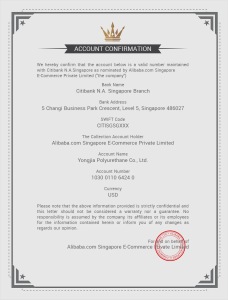

- Certifications & Quality Assurance: Always verify international certifications. Yongjia's equipment complies with stringent standards, holding recognitions that assure safety and performance. This commitment to quality is a cornerstone of the yongjia polyurethane brand promise.

- Global Experience & Customization: With exports to over 60 countries, Yongjia understands diverse market needs. They don't just sell a standard pu seat machine; they offer customized solutions tailored to specific production lines and challenges.

- Comprehensive After-Sales Service: A machine is only as good as the support behind it. Yongjia provides 24/7 customer support, technical training, and maintenance services, ensuring your pu foam machine operates smoothly for years.

International certifications held by Yongjia Polyurethane, affirming product quality and safety.

Step 4: Consider Production Capacity and Automation

Analyze your current and future output goals. A small pu chair machine might suffice for a workshop, while a large furniture factory may need a fully automated line with multiple pu sofa machine stations. Key questions include:

- What is the required output (parts per hour/day)?

- Do you need a simple dispensing machine or a complete turnkey production line?

- Is robotic arm integration or PLC control necessary for consistency?

Yongjia Polyurethane excels here by providing "a full range of one-stop supply solutions from raw materials, equipment, molds to the entire production line." This integrated approach, visible in their modern factory setup, guarantees seamless scalability.

The advanced production factory of Yongjia Polyurethane, where reliability and innovation are built into every PU machine.

Conclusion: Making the Strategic Choice

Choosing the right PU machine—be it a pu pillow machine, pu freezer machine, or a high-end PU Spray Foam Machine—requires a balance of application knowledge, technical understanding, and partner evaluation. By following this guide, you position your business for efficiency and growth.

For over a decade, Yongjia Polyurethane has been the partner of choice for global manufacturers, offering the perfect synergy of innovative technology, proven reliability, and unmatched customer service. Their diverse portfolio ensures you find not just a machine, but a solution.

Ready to Find Your Perfect PU Machine?

Contact the experts at Yongjia Polyurethane today for a personalized consultation. Visit their website to explore their full range of polyurethane equipment.

Phone/WhatsApp: +86 13656166310

Email: info@pufoammachine.com

Website: www.pufoammachine.com

Address: Room1101, No.4 Shashan Road, Jiangyin City, Jiangsu Province, China.